Cole Carbide Industries: Global Leader in Carbide Cutting Tool Solutions.

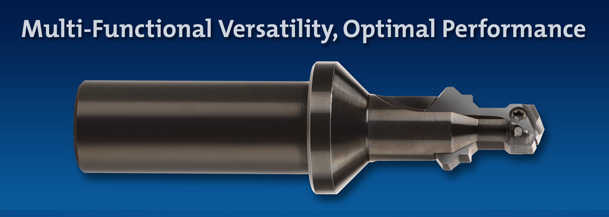

Cole Carbide is the leading manufacturer of precision-ground carbide cutting tool solutions and cutting tool systems. Cole satisfies diverse market application challenges by offering standard products and custom engineered solutions through manufacturing facilities, distribution centers and sales outlets located worldwide.

The Cole Family of Companies is defined through three subsidiaries – Cole Carbide Industries for Cole Engineered Products and Cole Tooling Systems for Cole Oil, Gas & Water, Millstar Tooling, Omnithread Milling, and Indexa-V Carbide Drilling Products, and Cole Diversified Products for the Rivit Group.

Cole Carbide Industries, Inc., is headquartered in Orion Township, Michigan and is ISO 9001:2015 Certified with DNV-GL

About Cole Carbide

Cole Facilities - Cass City, Michigan

Part of the Cole tradition of excellence is the continuing commitment to facility upgrades, expansion and improvement. For example, recent investment has made Cole's carbide manufacturing facility in Cass City, Michigan one of the finest and most efficient in the industry.